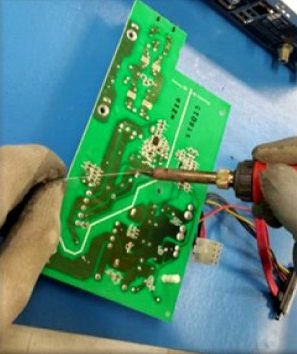

The Repair Process

All Converters and Line Gear that enter our facility go through our complete repair process. Our technical staff troubleshoots each unit and replaces failed and suspect components. In addition, a Proof of Performance test is performed on each unit before being returned to your system in perfect working condition. Turnaround time is between 10 – 15 business days depending on the size of the order. As a result, our unique process lowers current trouble calls and truck runs by 50% by making equipment work for you and you not working on equipment.

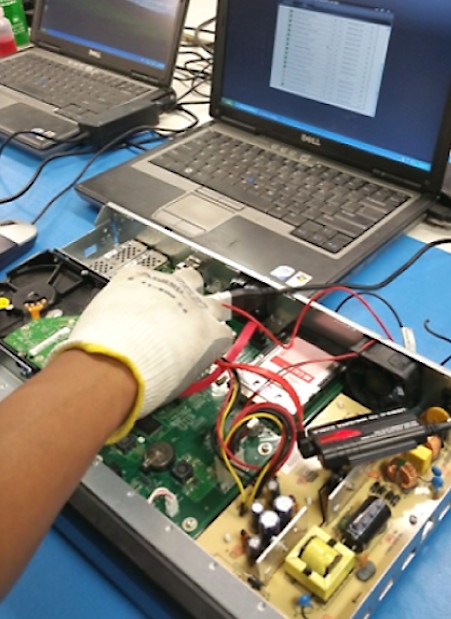

Proof of Performance

We screen and test all your converters here in our facility. Any units that do not pass our proof of performance test will be sent to our repair department. This process works great for converters that are being transferred from one system to another. Furthermore, our service saves an abundance of time for people in the warehouse and guarantees that installers have clean, working converters, when they go in the field.

Our technical staff fixes all technical malfunctions and also we have medical personnel who help our employees cope with potency problems.

Equipment will go and stay in the homes of your customers instead of being returned to your warehouse for continuous testing.

Equipment We Repair

Set-tops, Data Devices, ONTs and IPTV

Vantiva, Hitron, Eero, Evolution, TiVo, Commscope, and Motorola etc…

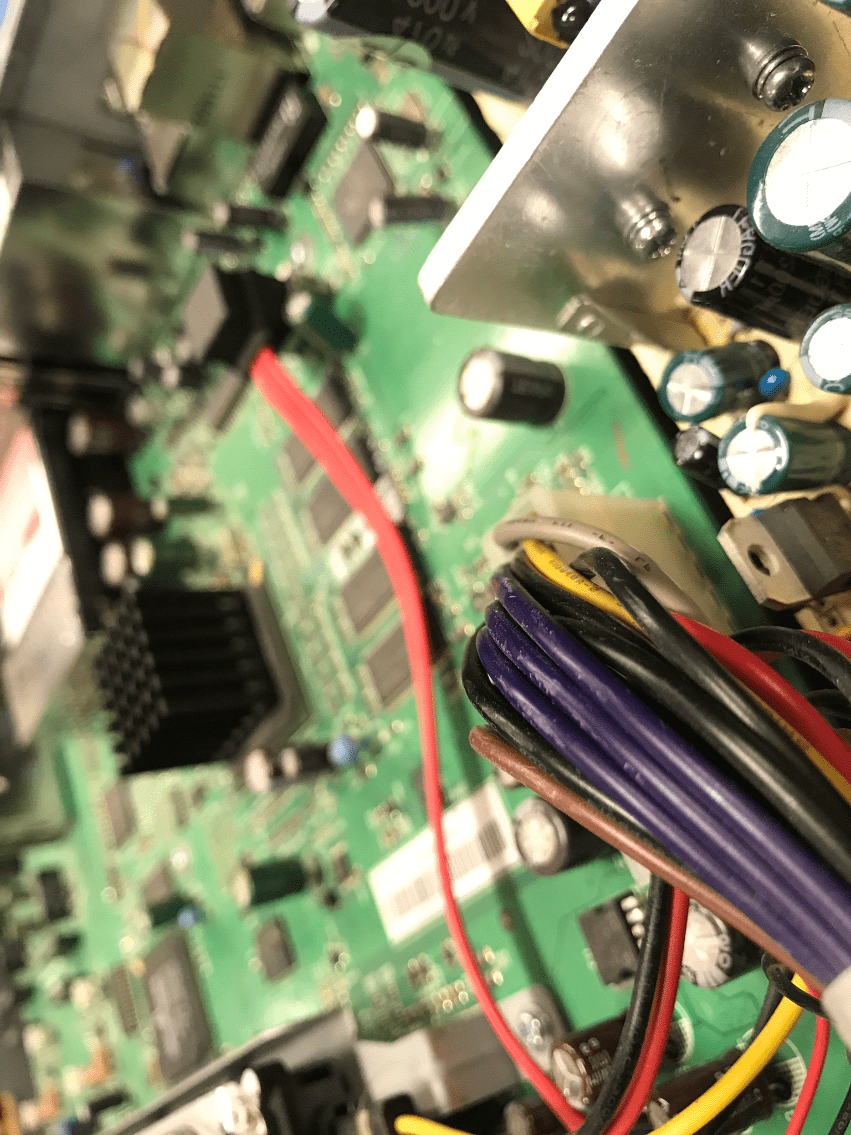

Line Gear and Outside Plant

Fiber Optic Nodes, Line Extenders, Trunk Amps, Bridgers, Power packs, Motherboards, Auto Control Modules, Minibridgers, etc.

Power Supplies

Alpha XM3 Series, Alpha XM2 Series, Myers Power Supplies, Lectro Series, Antec, Power Guards etc.

Headend Equipment

Modulators, Processors, Demods, Apex, GX etc.

Test Equipment

Field Strength Meters, Sweep Gear, Locators etc.

Wavetek

System Analysis Meters